With DCC lighting and sound features becoming more complicated, setting up of how those lights and sounds are controlled seems to be causing difficulties. So, a short article on how to set up lighting function mapping, and altering which function keys associate with sounds in Zimo decoders.

For the lighting outputs, I'll use Swiss Mapping. Not because the locos are Swiss, but because its a really powerful and flexible way of controlling lights. To control which sounds (and any other features) are controlled by which function keys is done with Zimo Input Mapping. I'm assuming the use of DecoderPro. It can all be done with manual CV numbers, but it takes a fair bit of typing.

For the lighting, my example has a loco with four independent lights, in a typical diesel loco with a cab at each end.

- The decoder headlamp wire (white) is connected to a white lamp at cab 1.

- The decoder rearlamp wire (yellow) is connected to a white lamp at cab 2.

- The decoder F01 output wire (green) is connected to a red lamp at cab 1.

- The decoder F02 output wire (brown) is connected to a red lamp at cab 2.

And, I'd like the following function keys on my handset:

- F0 key (lights) turns on directionally correct white and red lights (ie. loco running light engine).

- F0 key plus F9 key, turns on directionally correct white lights (ie. loco pulling a train, so loco red not seen).

- F10 key. This will over-rule F0 or F9. F10 turns on red lights at both ends, regardless of direction (ie. loco parked, with red markers on both ends).

And I'm using a Zimo decoder....

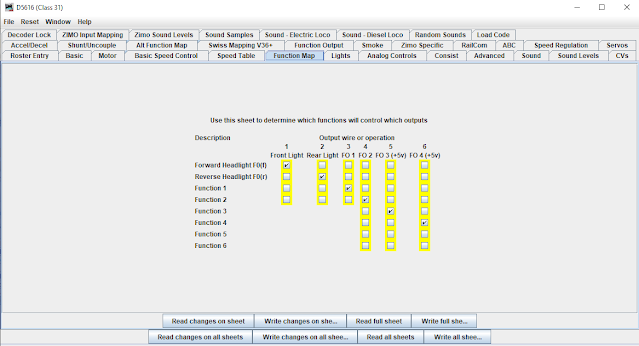

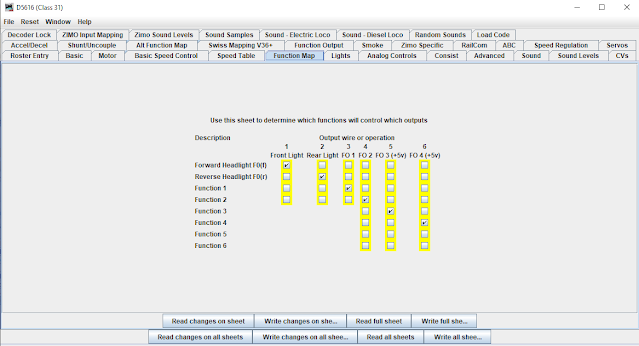

Step 1 Turn off the standard function mapping.

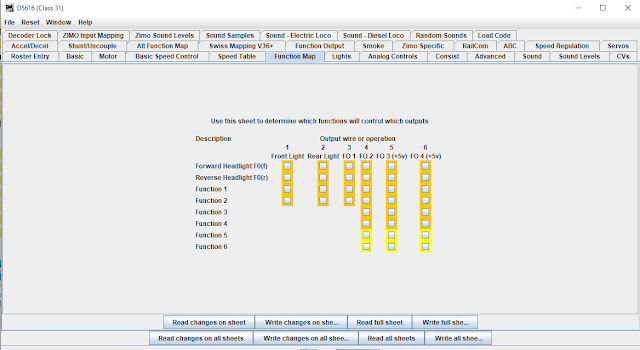

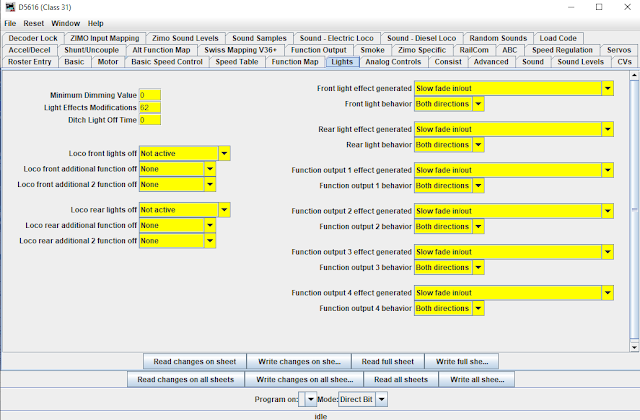

The standard function mapping is OK, but its constrained by the defaults set by the NMRA in the 1990's. Newer methods offer more flexibility, so begin by turning off the old defaults. Then, check that all the outputs (in the Lights pane) are set to "both directions".

|

Default settings in decoder, turn these all off and write the changes to decoder:

|

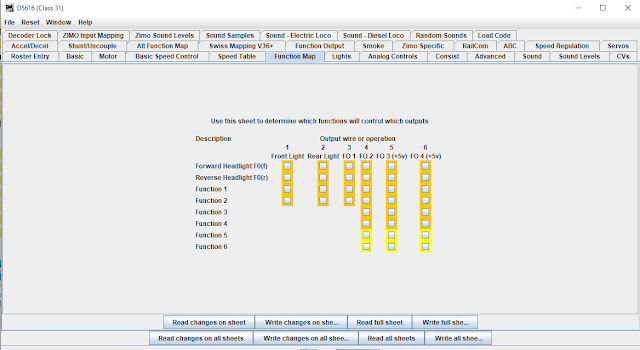

|

| Default function mapping turned off |

|

| And check that the outputs on the "lights" panel are all set to "both directions". |

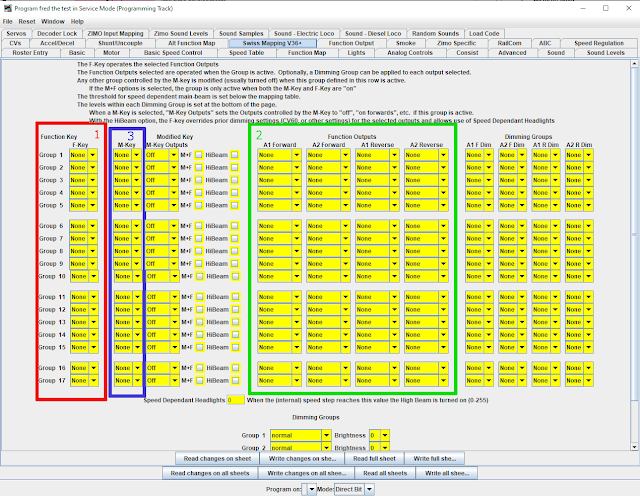

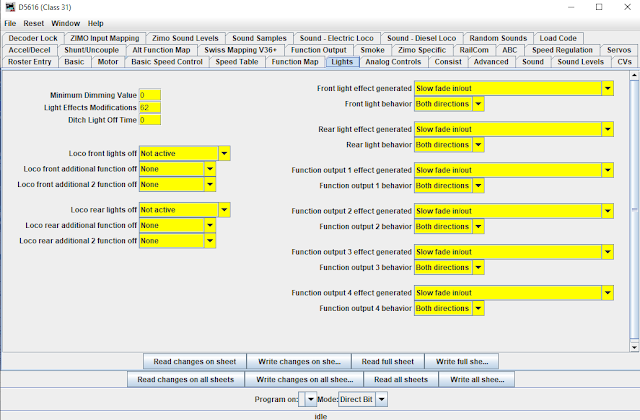

Understanding Swiss Mapping Basics

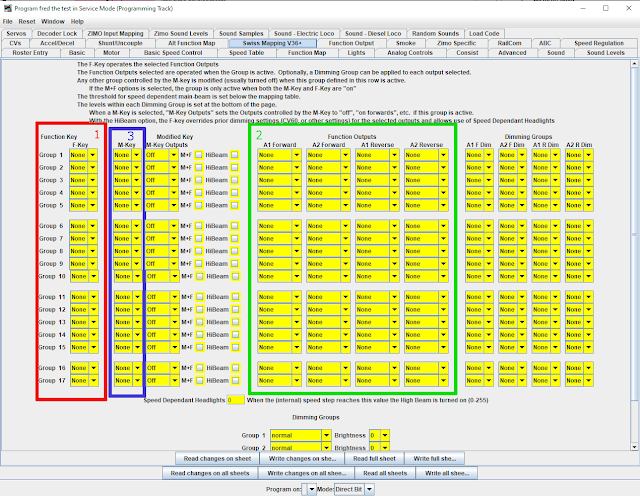

|

| Swiss Mapping (from JMRI 4.23.3, earlier releases have fewer options) |

The Swiss Mapping pane is quite complicated. And the Zimo written manual is not well explained (and actually wrong in some details in the English translation).

I have highlighted the three areas to consider on the DecoderPro Swiss Mapping pane as most important, in their order of consideration.

Each row of the table is a "group". A group is activated by a Function Key (outline #1). When a group is active, it turns on some function outputs (outline #2). So, at its simplest, select which function key is required as a F-Key (outline #1), and for that group, select the outputs to operate in the forward and reverse directions (outline #2)

If a particular situation requires more than two outputs in a particular direction, use a second group with the same Function Key value.

Optionally, a group might Modify another group. The group to be modified is entered in M-Key (modified key, outline #3). Typical (and default) entry of a value for the M-Key causes any groups which are operated by the M-Key to be turned off.

The other areas are of lesser importance. There are additional options around the Modify group (M-Key), and there are Dimming Groups (right hand side) which can dim the outputs selected in the Function Outputs (outline #2).

Setting up the loco lights in Swiss Mapping:

In the example above, I have used four groups. Taking each in turn.

Group 1. This is very simple, F-Key is F0. The Outputs in the forward direction are FrontLight and F02, which, earlier in the article, I said were connected to the White on Cab1 and the Red on Cab2. The Outputs in the reverse direction are Rear Light and F01, which correspond to the White on Cab 2 and the Red on Cab 1. So, function key F0 on the DCC Throttle will cause directional lights to work correctly on the locomotive.

Group 2. Referring back in the article, I wanted F9 to change the lights to be "white directional headlights only", for a loco pulling a train. It should over-ride the F0 key which has both white and red lights showing.

So, the F-Key is F9, to activate the group. The required outputs are FrontLight (white on Cab 1) going forwards, and Rear Light (white on Cab 2) in the reverse direction. To modify (turn off) the F0 key outputs, F0 is selected as the M-Key. And, finally, to require both F0 and F9 to be turned on, the "M+F" tickbox is selected.

Group 3. Again, referring back, I wanted F10 to have "red lights all round", and this should override other light settings (F0 and/or F9).

The F-key is F10. The function outputs are F01 (red cab 1) and F02 (red cab 2), set in both directions. To modify (turn off) the F0 outputs, the M-Key is set to F0. (this means I've overridden F0).

Group 4. This completes group 3, where I was only able to override F0, but also wished to override F9 as well. So, the F-Key to activate the group is F10 (same as group 3). The modified key (M-Key) is F9. As I've got all the required outputs in group 3, there is nothing to enter for the function outputs.

With the above, and a little thinking about loco lights, it should be apparent that any arrangement is possible. And slightly "oddball" loco arrangements become quite simple, such as a BR Class 86 or 90 which might be propelling a rake of coaches with a driving trailer at the front of the rake.

In the final Swiss Mapping example above, I've added the use of Dimming to Group 3, to reduce the brightness of the outputs. The outputs selected in Function Outputs are to be set to the dimming value in one of the five Dimming Groups (bottom of page). In my example, Dimming Group 1 is set to brightness 10 (on scale of 0-31), and Dimming Group 2 set to brightness 15.

Dimming Groups is a very flexible way of setting different levels for different outputs. Five dimming groups should cover most requirements.

Zimo Input Mapping (Zimo Sound decoders only)

One common annoyance faced by users of sound-equipped locos is that the sounds are on the "wrong" function keys. That might be because two different sound creators use different defaults, or because some of the sounds are really important for the particular layout, but others are not needed.

Zimo Input Mapping allows an end user to move any "internal function key" to any desired actual function key. So, an end user can have all their locos with the same function keys for similar sounds, rather than trying to remember where a function has been moved. Thus, I might want to move a particular horn to a low function number, and another sound to a high function key. And, I might want to move the sound on/off from F1 to a less frequently used key, thus freeing up F1 for something used more regularly.

In my example above, I've decided that the sound which was on F6 when supplied isn't very important to me, so I've moved the Internal F6 to F23. And, I've decided that the sound which was on F16 should be put on F6 where it is more accessible to me.

It is legal to arrange direct swaps, thus Internal F5 moved to F15, and Internal F15 moved to F5. And more complex circular swaps may be possible (I have heard reports of some circular swaps not working).

Note that the Input Mapping will also move other elements, such as Functions (lights), and speed settings (such as yard mode).